Custom Silicone Extrusions

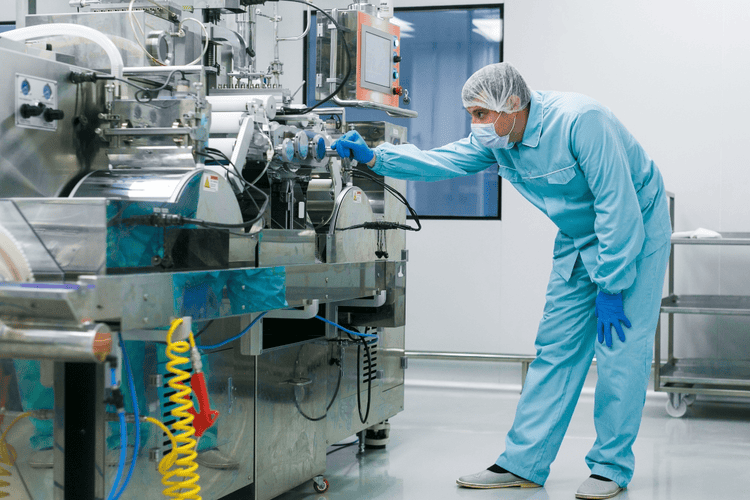

Thanks to advances in production capabilities over the last 30 years, the custom silicone extrusion process has become more accessible. Subsequently, silicone has become the go-to elastomer for use in engineered products.

We regularly supply engineers, manufacturers, and inventors with tubing, cords, and bands, as well as more complex profile shapes or molded products from solid silicone and other elastomers. In addition to that, we also produce open cell or closed cell silicone foam. Using the extrusion process, the finished product can be manufactured in continuous lengths or cut to length and packaged to meet the customer’s usage needs. Lastly, we can imprint your product information, logos, or graphics on the finished product.

Custom silicone has become a popular option for addressing the extreme operating conditions found across many major industries. At ARCO Silicone, we use our extensive silicone extrusion capabilities to provide our customers with solutions to overcome a variety of operational challenges.

What are Silicone Extrusions?

Silicone extrusion is the process in which silicone is forced through a shaped die in to produce a continuous formed length of material with complex profiles and cross-sections. As a synthetic rubber, the elastic properties of silicone make it an ideal material for use in the extrusion process.

At ARCO Silicone, we can provide silicone extrusions in a broad range of profiles, including:

- “D” profiles

- “e” profiles

- “H” profiles

- “L” profiles

- “T” profiles

- “U” profiles

- Omega profiles

- Wedge profiles

- Custom profiles

While we can extrude a vast array of silicone products, some of the items we commonly produce include:

- Finned tubes, which are instrumental in transferring heat from heated fluids to cooler fluids through a tube wall.

- Silicone rubber gaskets to create high-performance seals in harsh or high-temperature applications.

- Silicone sponges, a longer-lasting, more eco-friendly alternative to common cellulose sponges.

What are some benefits & features of extruded silicone products?

![]() Extruded silicone parts and components offer numerous benefits across industries, such as:

Extruded silicone parts and components offer numerous benefits across industries, such as:

- Biocompatibility. Silicone is non-toxic and non-allergenic, which makes it unlikely to cause negative reactions with human tissue when used in medical devices and equipment.

- Resistances. As an inert material, silicone does not react with most chemicals or other materials. Silicone resists most bases, ultraviolet radiation, ozone, water, and oil. It also inhibits the development of molds and fungi.

- Dielectric strength. Extruded silicone materials act as a good electrical insulator and won’t degrade under typical exposure to current.

- High temperature resistance. Most common silicone extrusions can deal with temperatures as high as 500°F. Silicone extrusions are also flame retardant.

- Elastic memory. Silicone extrusions feature excellent elastic memory, ensuring they will maintain or return to their original shape after exposure to high pressures or compressive forces.

- Transparency. Extruded silicone’s relative clarity makes it easy to color or to use in clear tubing.

At ARCO, we pride ourselves on our ability to design custom silicone extrusion products to meet virtually any need. Our manufacturing processes adhere to many industry standards, such as FDA 26CFR, ISO 9001:2015, ASTM, ITAR, Buy American Act, WOSB, and MIL-STD-105e. We can also develop unique formulations to meet specific application requirements.

For further examples of our work, please review some of our case studies. If you are interested in working with us, please request a quote or contact us.

| GENERAL CAPABILITIES | Custom, Small Run, Compound Development |

| EXTRUSION PROCESS | Cold, Silicone extrusion |

| MAX. EXTRUSION WIDTH | 5.0 inches (Generally, other profiles can be determined on a case by case basis) |

| MAX. EXTRUSION LENGTH | Continuous |

| MATERIALS (NON-METALS) | Foam Silicone, Silicone |

| EXTRUSION PRODUCT | Finned Tubes, Profiles, Seals, Silicone Sponges, Tubing |

| EXTRUSION PRODUCT FORM | Profiles, Tubes, Shapes |

| EXTRUSION FEATURES | Flexible, Food Grade, High/Low Temperature, Thin Gauge, UV/Ozone Resistant |

| ADDITIONAL SERVICES PROVIDED | Imprinting Capabilities; Converting Services |

| PRODUCTION VOLUME CAPABILITIES | Prototype, Small Volume, Large Volume |

| LEAD TIMES | Quoted on job by job basis |

| EFFICIENCY | Lean Manufacturing |