Industrial Silicone Rubber Products

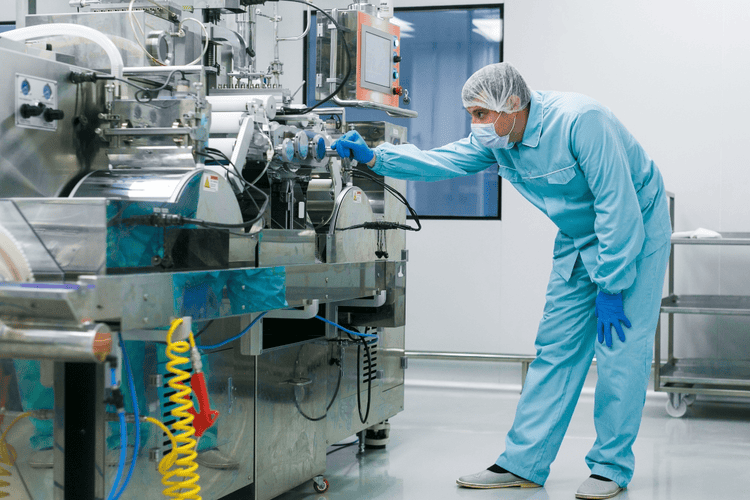

Silicone rubber is a versatile material that offers many beneficial properties such as high-temperature performance, transparency, durability, and great electrical insulation properties. These features, along with many others, make silicone rubber a highly desired material in the Industrial markets. Whether you need a custom extruded gripper cord for packaging machinery or a custom molded silicone piece for metal-detectable equipment, we offer complete services from prototype to production.

Our industrial products are usually made of materials such as silicone, fluorosilicone, dimethyl silicone, and foam silicone, but other elastomers such as EPDM and synthetic rubber are also useful depending on the usage.

We create custom parts for Industrial applications such as:

- “D” profile gripper cords for packaging machinery

- Metal-detectable cords

- U-channels

- Rubber gaskets & seals

- Water system O-rings and hoses

- Tubing

- Grommets

- Belts

- Wire and cable harnesses

We also manufacture industrial products for extreme environments.

These industrial parts and components offer numerous benefits in extreme environments such as:

- Resistances. As an inert material, silicone does not react with most chemicals or other materials. Silicone resists most bases, ultraviolet radiation, ozone, water, and oil. It also inhibits the development of molds and fungi.

- Dielectric strength. Extruded silicone materials act as a good electrical insulator and won’t degrade under typical exposure to current.

- High temperature resistance. Most common silicone extrusions can deal with temperatures as high as 500°F. Silicone extrusions are also flame retardant.

- Elastic memory. Silicone extrusions feature excellent elastic memory, ensuring they will maintain or return to their original shape after exposure to high pressures or compressive forces.

- Transparency. Extruded silicone’s relative clarity makes it easy to color or to use in clear tubing.

At ARCO Silicone, we pride ourselves on our ability to design custom silicone extrusion products to meet virtually any need. Our manufacturing processes adhere to many industry standards, such as FDA 26CFR, ISO 9001:2015, ASTM, ITAR, Buy American Act, WOSB, and MIL-STD-105e.

As a custom rubber manufacturer in the U.S. for over 100 years, ARCO Silicone is equipped to formulate custom compounds specifically designed for your application. We can manufacture your product in a variety of colors (including PMS color match).

For further examples of our work, please review some of our case studies. If you are interested in working with us, please request a quote or contact us.

Are you a manufacturer looking to reshore products in your supply chain?

Contact ARCO Silicone to discuss your options. As an American manufacturer, ARCO Silicone can provide shorter lead times and lower minimums. You can depend on our team of skilled engineers.